Simulation of straightening processes

Period: 2004 to 2019

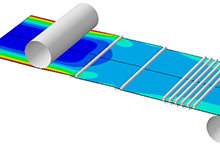

Objective: Straightening processes are used to improve the flatness of metal strips after the rolling process. During bend straightening, residual stresses in the strip are relieved by repeated plasticizing at the bending rolls. CAE Simulation & Solutions GmbH has developed numerical methods for efficient analysis and optimization of straightening lines over many years. These methods are based on an Euler formulation in which the material “flows” through a standing mesh.

This allows rapid predictions of what ripple and residual curvature a strip will have after passing through the line.

Partners/funding agencies:

- Former company BWG, Duisburg

Results:

The Euler formulation reduced the analysis time of a configuration to a few hours. This increase in efficiency led to the development of new types of equipment with significantly better straightening results (BWG-Levelflex).