Bead optimization

During the development of a new container with a higher payload and adjusted to higher snow loads, which are referenced in the national appendices of the Eurocode, a new design of a roof for a storage container was developed. Three development goals were defined at the beginning of the project:

- Automisation of manufacturing processes using bent sheet metals

- Increase of the payload of the roof (Snow loads according to Eurocode 1)

- Streamlining of the production process by omitting supporting struts

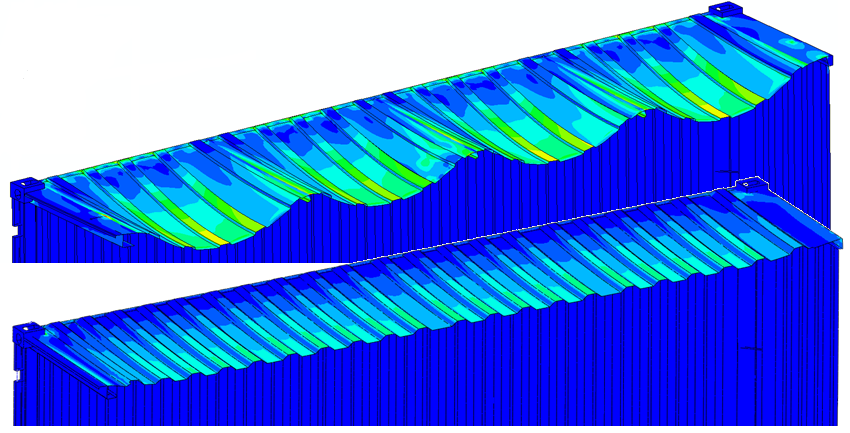

By switching from support struts to a self-supporting roof consisting of sheet metal, the beading of the roof was optimized, whereby the bead-height, bead-width and the distance between beads were available variables.

A parameter optimization, in coordination with the customer and considering the manufacturing possibilities and also the geometric boundary conditions of the initial metal sheet, led to the development of a roof which was improved in many ways. Optimizations:

- Reduction of deflection

- Reduction of the maximum stresses

- Concept for common parts

- Simplified process for the mounting of the roof

The image depicts the colorized equivalent stress in the initial state (top), and the optimized version (bottom). The stresses are super imposed on the structure using a deformation scale of 100.