Extending the operating time of the extraction system

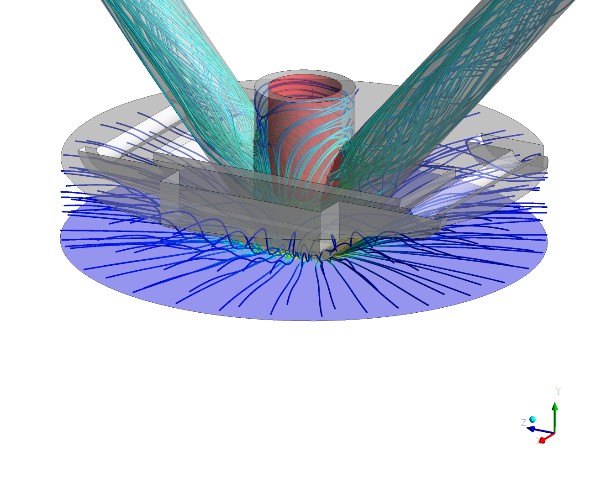

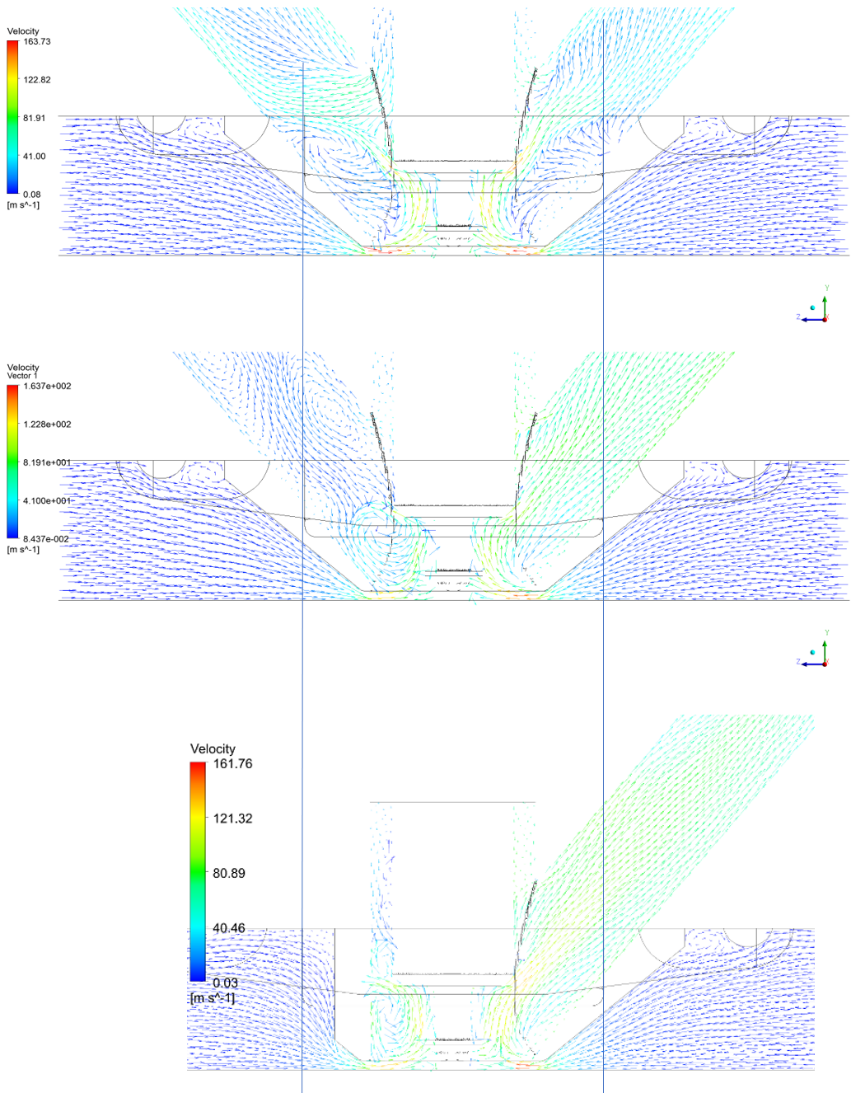

The task in this project was to reduce blockages in the extraction system (plugging of plaster) of a milling system for plasterboard, which was causing the system to shut down. The aim was to increase the service life of the system by reducing the deposits in the extraction system. Therefore, 3D flow simulations of the extraction system in the immediate area of the extraction head were carried out.

The original state shows recirculation areas AND an inconsistent velocity distribution in the pipe cross-section. A one-sided extraction system shows significantly better results with unchanged geometry. Ultimately, adapting the extraction cross-section to the original state and optimizing the intake angle results in the best solution without changing the system data (volume flow). However, this reduces the pressure loss and therefore the required capacity.