Composite Front

Verification of the composite components of the end car front in the TSB project.

The end wagon front consists of fiber composite components in combined CFRP / GFRP construction with cover layers made of GFRP fabric layers and UD CFRP reinforcements in individual components as well as corresponding foam cores. Inserts made of HGW 2372.1 hard glass fabric for connection to the consoles form the interface to the wagon body.

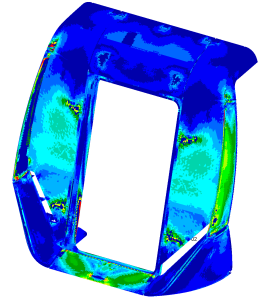

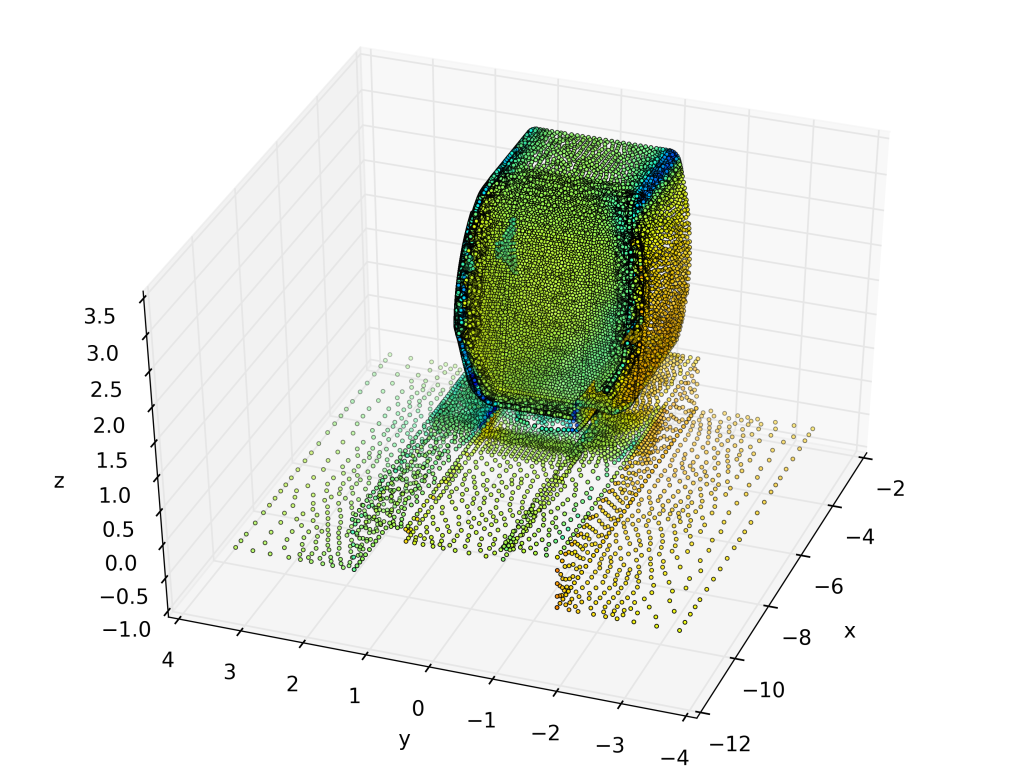

The simulation model was realized as a finite element shell model with location-dependent, orthotropic material properties, according to the local layer structure of the various assemblies of the composite front.

The strains (Max. Principal Strain) and the longitudinal and transverse stresses in the single layers (Max. Principal Stress) were evaluated. The evaluation was based on 0.4% strain analogous to aircraft construction applications.