Metal forming process

The project content which handled the underlying basis of the ECAP forming process, in which solid titanium is pressed through a 90° or 45° bend in a pipe-bend with constant cross-section.

In this preliminary study, simplified models were first used to determine the numerical effort required for such an analysis.

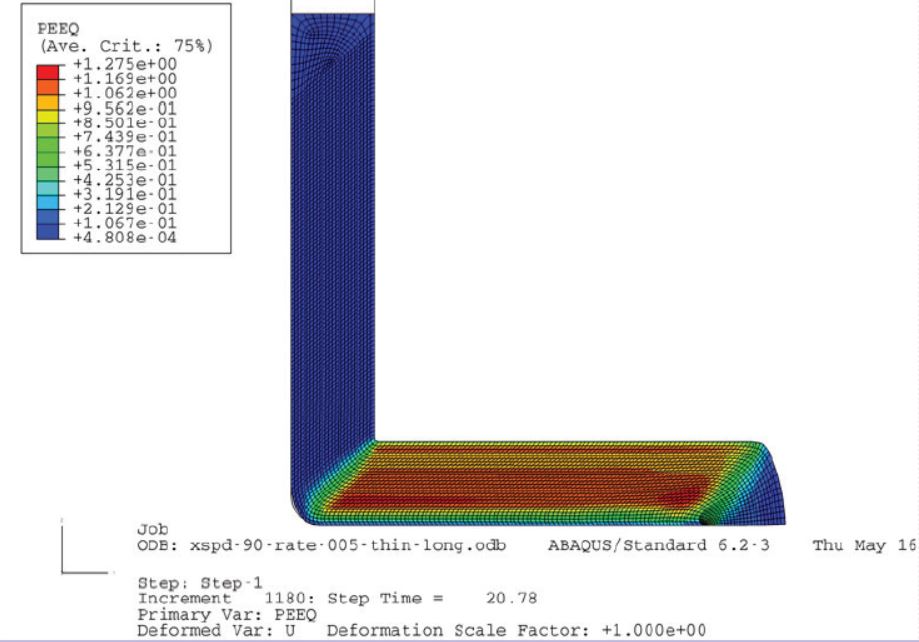

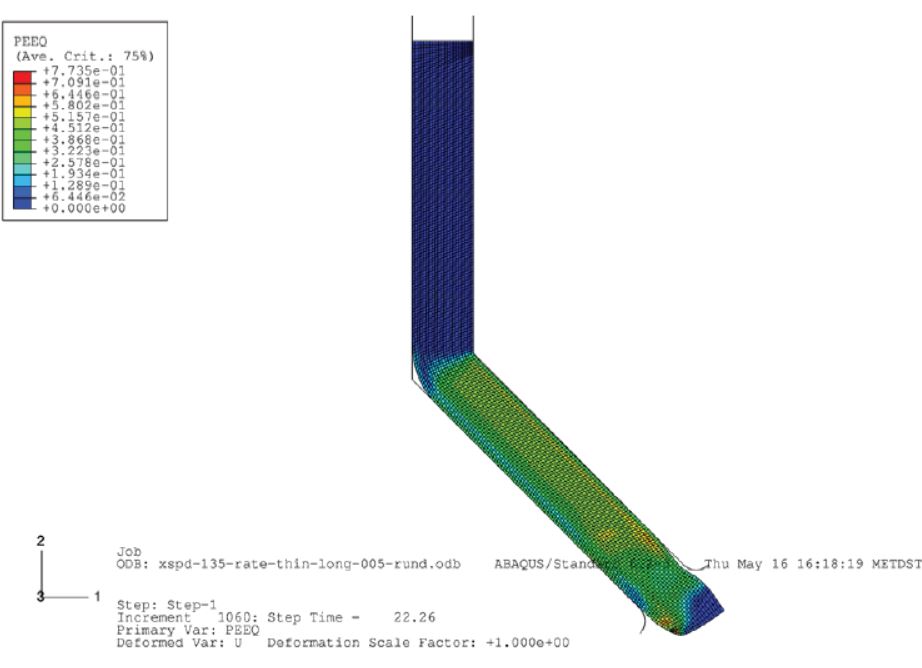

Subsequently, the loads to which the die is exposed to and the uniformity of deformation of the generated workpiece were calculated.

Comparative plastic strain using 90° tooling.

Comparative plastic strain using 135° tooling.