Fuel lines

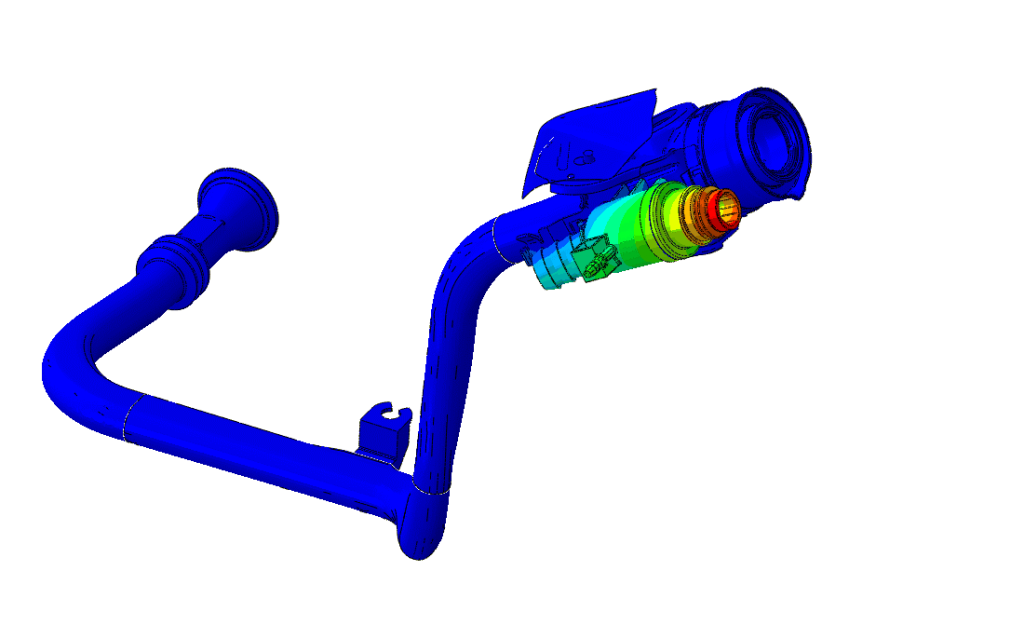

Nowadays, the filler necks of automotive tanks represent a complex assembly that must ensure safe refueling of the vehicles and at the same time prevent the escape of gases during refueling. Various loads occur at the filler neck, including a load case in which a person leans against the nozzle (“drunken canadian”). The mechanical calculation of the entire filler neck, which consists of welded stainless steel components (bracket) but also plastic parts (flow guide, …), is considered as a complete assembly including the downstream fuel line to the tank. This is necessary because the rigidity of the tank line resists the tilting of the filler neck.

The results are in good standing with the tests. The highly complex plastic parts and thus the tools for their production could be simplified and verified before they are sent into large-scale production.