Bike frame

In cycling, as in other areas, weight is a major factor. Attempts are made to achieve a minimum weight by changing materials and geometry.

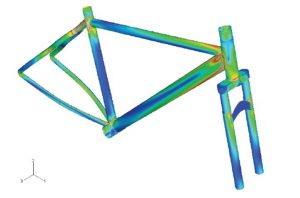

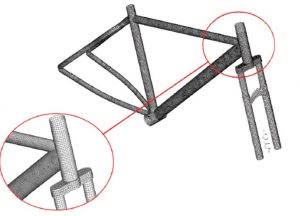

The “Bicycle Simulation” project is concerned with investigating the effects of different load cases on the bicycle frame.

The aim is to find out which areas of the (metal) bicycle frame or suspension fork are critical under which load conditions and how these areas can be optimized by changing the geometry.

The following focal points are to be considered in the calculation:

– Interactions of the individual components

– frame

– suspension fork

– Suspension fork

– Real function

– Spring constant

– Plain bearing condition

– Tube contact

The result:

The calculations show that the use of FEM provides useful results, especially for assemblies, since the interaction of the components can be modeled realistically.

On the frame, the areas with tube intersections in particular exhibited higher stresses. Here, optimization is performed by varying the geometry, such as changing the wall thickness or the tube diameter, and by iterative calculations. An additional buckling calculation determines the safety of the pipes against “buckling.”

*Note: This project is a demo project for experimental purposes, NOT an industrial project!