DMU Membrane

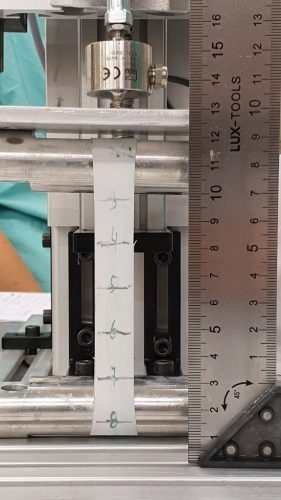

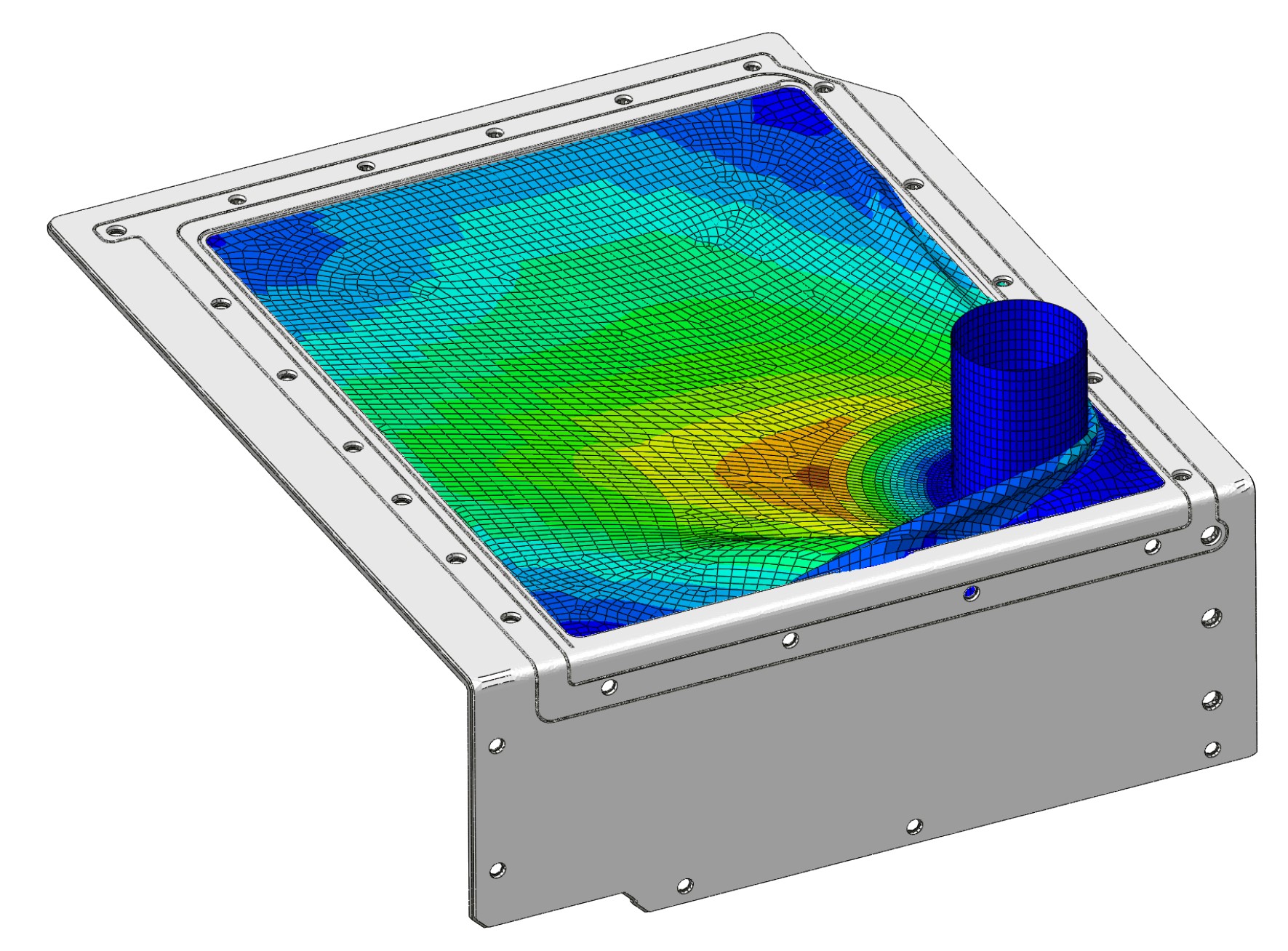

The aim of the project was to calculate the strains in a silicone membrane for sealing a milling machine. Since no material data was available for the used material, uniaxial tensile tests were carried out on the tensile testing machine at CAE Simulation & Solutions. Based on this, a hyperelastic material model (Mooney-Rivlin or Ogden) was developed.

In several simulations, a good agreement of the deformation pattern with the real structure was achieved. The verification of the model was followed by variant studies. The results led to an optimization of the membrane by reducing the elongation of the membrane and thus to an extension of the service life.