Car body

As a result of the project, a number of new approaches to the optimal design of this area of the vehicle were identified which were not based on previous designs.

The optimizations were carried out using the EN 12663 for Steel components, the DVS 1608 for Aluminium components used in integral design methods, and the DVS 1612 for the Steel components used in differential design methods.

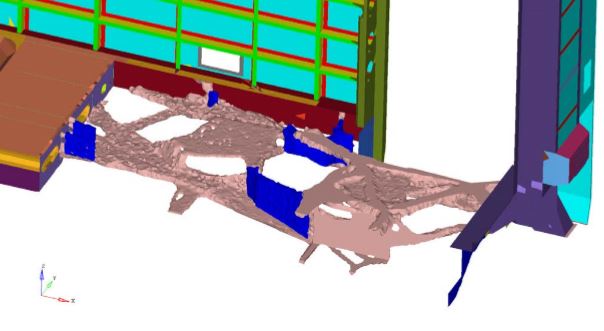

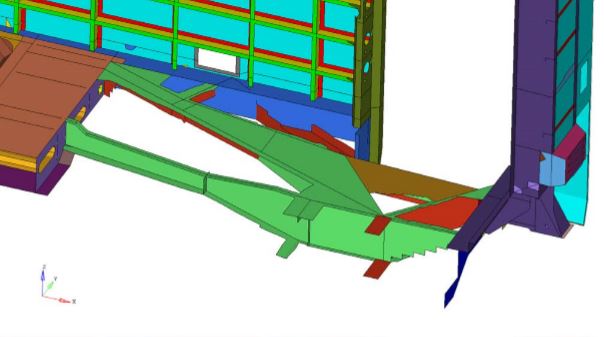

These general 3D topology optimization results were analyzed in regard to their potential and manufacturability and then transferred to a welded steel structure. This was in turn weight-optimized with respect to the used plates, plate thicknesses and cutouts using various optimization algorithms.

Substantial savings in both weight and weld length (manufacturing costs) were achieved.

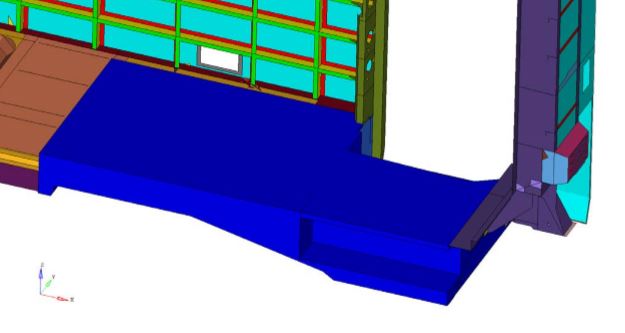

The figures show, from top to bottom, exemplary stages from the course of the project.