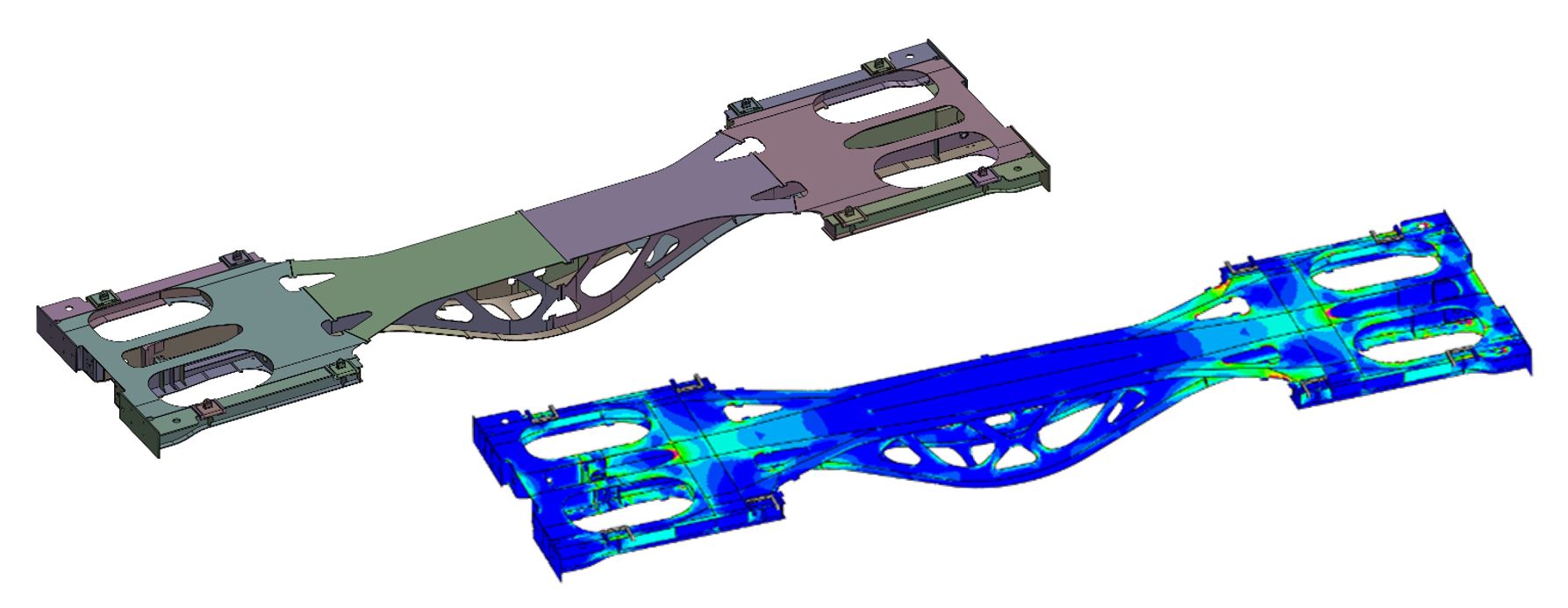

Freight wagon base frame

The aim of this project was to optimize the weight of a freight wagon base frame in order to increase the payload. Using high-strength steels (alform700) and the method of topology optimization, a frame was developed which is used for transporting iron ore. Therefore, in addition to the highest possible payload, a design composition suitable for sidings, a 2x33ft arrangement, was chosen.

The welding plans for the frame were defined on the basis of the calculation results and in accordance with EN15085-3 for weld seam class CP C2!

The model was created, calculated and evaluated as a shell model in accordance with the state of the art of finite element simulation.

The design included the evaluation according to the FKM guideline for the static design ( including the plastic support coefficient) as well as a DVS1612 evaluation regarding the service life of the base material and the weld seams.

The load was applied using the loads specified in EN12663-1 and EN12663-2 for freight wagons with planned container superstructures.