CAMed – Clinical Additive Manufacturing for Medical Applications

Timeframe: 2019-2023

Goal: The aim of this research project was to develop additive manufacturing processes that will enable the production of patient-specific implants for various medical applications directly in the clinic. A medical 3D printing center was established at the Medical University of Graz. In the project, we perform simulations on FEM models of human structures (thorax, upper arm, skull) based on patient-specific imaging data (CT, MRI, ..) and determine the stiffness of the bony and cartilaginous structures in order to subsequently design implants that have similar properties. The 3D geometry data of the implants were then produced using 3D printing and tested. Both metallic implants (titanium) and plastic implants (PEEK) were produced.

Partners/Funding agencies:

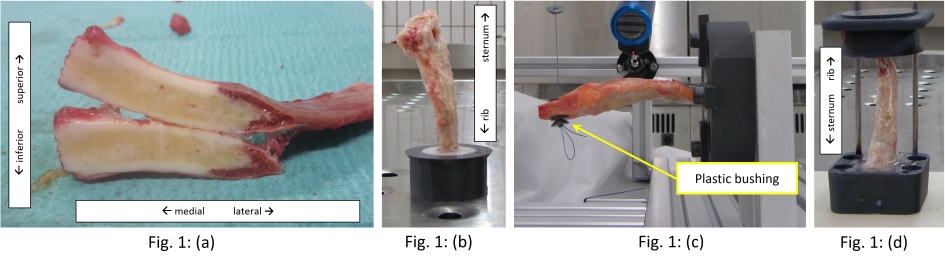

Result: Successful performance of measurements on ribs and cartilage in early 2020 at Meduni Graz to determine the mechanical properties of human cartilage tissue and the rib-vertebral joints.

You are welcome to inquire about the corresponding publications in the Journal of Biomechanics.

Simulations on complete thorax models (bones, muscle stiffness using springs, pleura, skin) during various physical activities to determine stiffness with/without rib resections: