The time when it was said that plastics and large deformations cannot be simulated is long gone. It is simply a matter of calibrating a correct material model and performing completely non-linear calculations.

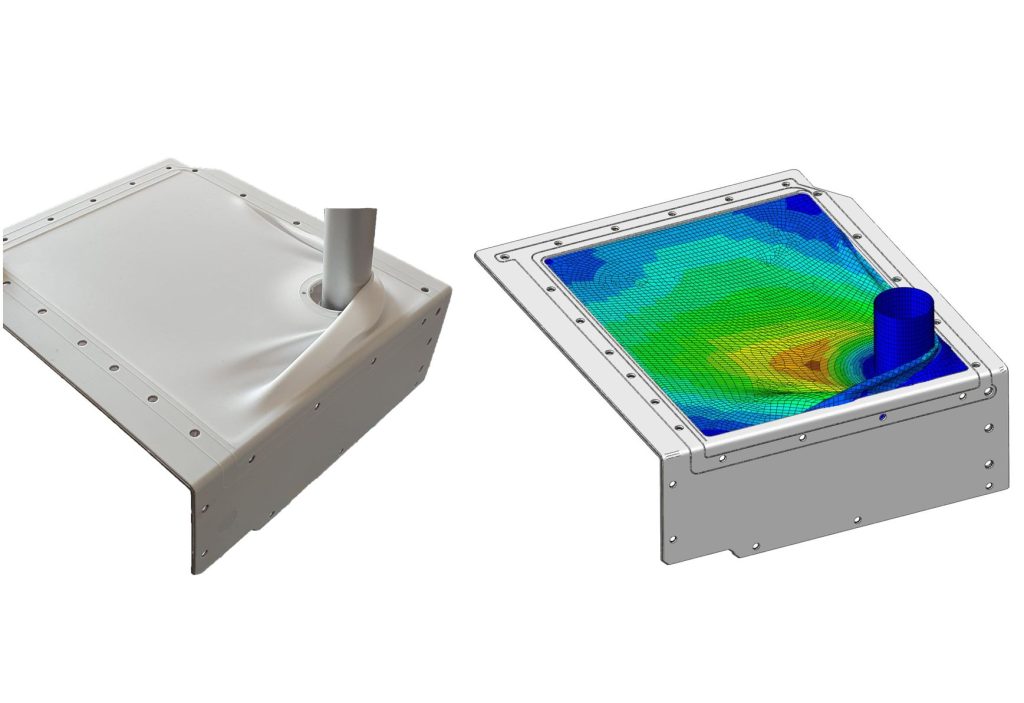

The aim of the project was to calculate the strains in a silicone membrane for sealing a milling machine. As no material data was available for the used material, uniaxial tensile tests were carried out on the tensile testing machine at CAE Simulation & Solutions. From this, a hyperelastic material model (Mooney-Rivlin or Ogden) was developed. In several simulations (geometry variants), a good match between the deformation pattern and the real component was achieved.

On our Youtube channel you will find a video showing all the positions approached during the entire milling process in the correct sequence: https://youtu.be/7JN99HjVMBw.